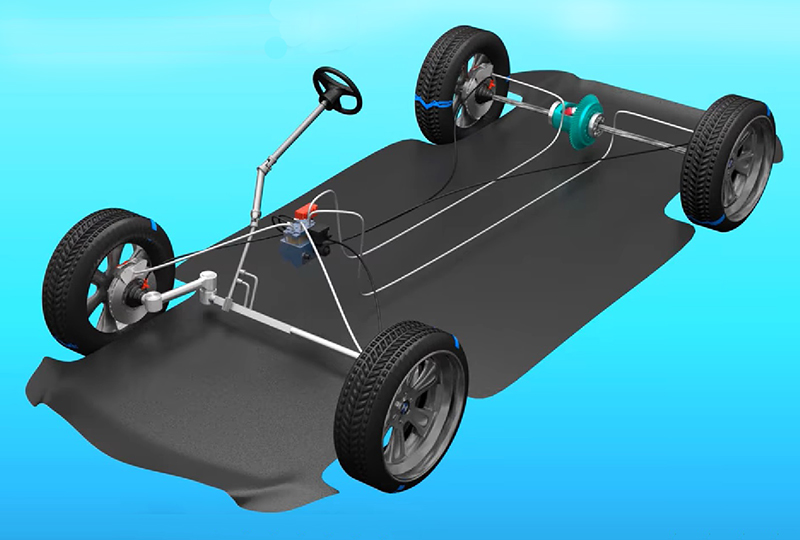

Anti-lock Braking System (ABS) is used in advanced automobiles to prevent slip and locking of the wheel after brakes applied. It is an automobile safety system, the controller is provided to control the necessary torque to maintain optimum slip ration. The slip ration denotes in terms of vehicle speed and wheel rotation. It’s an automated system that runs on principles of threshold braking and cadence braking which were practiced by skillful drivers with the previous generation braking system. Its response time is very faster so that makes it easy steering for the driver. ABS generally offer advanced vehicle control and minimize the stopping distance in the slippery and dry surface, conversely, on loose surfaces like gravel or snow-covered pavement, ABS can significantly increase braking distance, although still improving vehicle control.

Anti Lock Braking System Introduction

The anti-lock braking system (ABS) prevents brakes from locking during braking. In normal braking situations, the driver controls the brakes, however during severs braking or on slippery roadways when the driver the wheels to approach lockup, the antilock takes over here. The ABS modulates the brake line pressure independent of the pedal force to bring the wheel speed back to the slip level range that necessary to the optimal braking performance. The ABS does not allow a full wheel lock under braking. In simple terms, during the emergency of braking, the wheel does not get locked even if you push a full auto brake pedal and hence the skidding does not take place. It allowed drivers to control the car easier, even on roads with low adhesion, such a rain, snow, and muddy road. The brain of the antilock braking system consists of an Electronic Control Unit (ECU), a wheel speed sensor, and a hydraulic modulator. ABS is a closed circuit, hence it used the feedback control system that modulates the brake pressure in response to the wheel deceleration and wheel angular velocity to prevent the controlled wheel from locking.

Anti Lock Braking System Stopping Distance

The Stopping distance is one of the important factors when it comes to braking. Stopping distance is the function of vehicle mass, its initial velocity, and the braking force. Stopping distance can be minimizing by increasing in braking force (keeping all other factors constant). In all types of road surfaces, there is always exists a peak in friction Coefficient. An antilock system can attain maximum frictional force and results in minimum stopping distance. This objective of antilock systems, however, is tempered by the need for vehicle stability and steerability

The Stopping distance is one of the important factors when it comes to braking. Stopping distance is the function of vehicle mass, its initial velocity, and the braking force. Stopping distance can be minimizing by increasing in braking force (keeping all other factors constant). In all types of road surfaces, there is always exists a peak in friction Coefficient. An antilock system can attain maximum frictional force and results in minimum stopping distance. This objective of antilock systems, however, is tempered by the need for vehicle stability and steerability

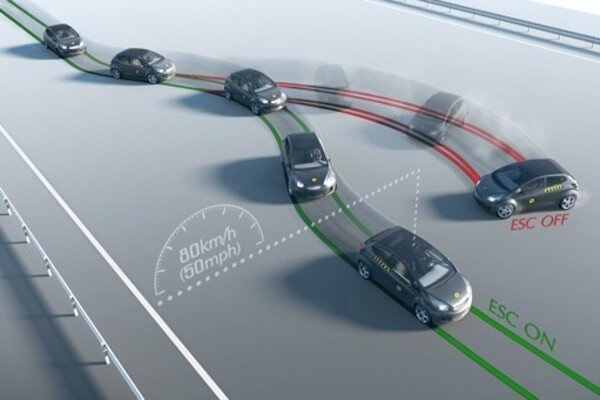

Stability

The fundamental purpose of the braking system is to decelerating and stopping of the vehicle, maximum friction force may not be described in some cases like asphalt and ice (p-split) surface, such that significantly more braking force is obtainable on one side of the vehicle than on the other side. So when applying the full brake on both sides will result in a yaw or skidding moment that will tend to pull the vehicle to the high friction side and results in vehicle instability. Here comes the concept of an antilock system that maintains the slip of both rear wheels at the same level and minimizes two friction coefficient peaks, then the lateral force is reasonably high thought not maximized. This contributes to the stability and is an objective of antilock systems.

Steerability

Good peak frictional force control is necessary in order to achieve satisfactory lateral forces and, therefore, satisfactory steerability. Steer ability while braking is important not only for minor course corrections but also for the possibility of steering around an obstacle. Tire characteristics play an important role in the braking and steering response of a vehicle. For ABS-equipped vehicles, the tire performance is of critical significance. All braking and steering forces must be generated within the small tire contact patch between the vehicle and the road. Tire traction forces as well as side forces can only be produced when a difference exists between the speed of the tire circumference and the speed of the vehicle relative to the road surface. This difference is denoted as a slip. It is common to relate the tire braking force to the tire braking slip. After the peak value has been reached, increased tire slip causes a reduction of tire-road friction coefficient. ABS has to limit the slip to values below the peak value to prevent the wheel from locking. Tires with a high peak friction point achieve maximum friction at 10 to 20% slip. The optimum slip value decreases as tire-road friction decreases.

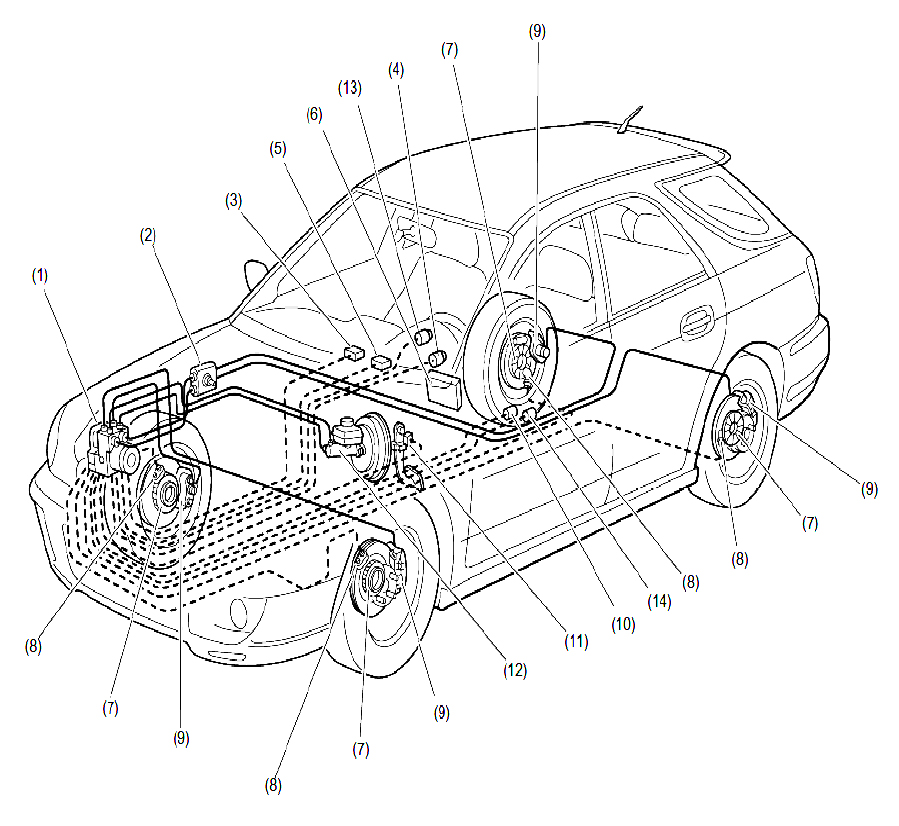

The function of Sensors and actuators

- ABS control module and hydraulic control unit (ABSCM & H/U)

- Two-way connector

- Diagnosis connector

- ABS warning light

- Datalink connector (for SUBARU select monitor)

- Transmission control module (AT models only)

- Tone wheels

- ABS wheel speed sensor

- Wheel cylinder

- G sensor

- Stoplight switch

- Master cylinder

- Brake & EBD warning light

- Lateral G sensor (STi)

[…] class of tyres. If there is one thing that defines this class, it’s speed. And whenever speed is involved, the grip is the key. You simply cannot go really fast without getting airborne. As such, the tires […]

[…] 16″ Disc […]

[…] cost-effective. It can be difficult to tell how long a shock will last through specifications alone, but checking out customer feedback can be a big help. Besides this, look out for relatively thick […]

[…] how to use? and what is a coolant about how they do work? Antifreeze or coolant is a very important component of an engine’s cooling system. Without coolants, it would be quite difficult to prevent an engine […]

[…] of tire/wheel imbalance that need correction – static (single plane) and dynamic (dual plane). Static balance addresses balance on only one plane – vertical movement which can cause vibration. A […]

[…] most crucial of the crucial components that are considered normal wear items, since they create the friction that helps stop your car when they are pressed against the brake disc (also called the brake […]

[…] and lots of options for smooth drive luxury and price in your budget and secure car with an airbag, abs, back camera, parking sensors, central locking, keyless entry, etc? then you need to visit our […]

[…] Brake System […]

[…] and traffic in the intersection if the intersection is clear I may turn but only if I have made a complete stop first for a flashing red light come to a complete stop behind the stop line just like you did it at […]

[…] you’d know this. Since the wheels on these toy cars were not ‘individually’ suspended, when you raise one corner of your toy car, the wheel on the same side of the elevated corner is also raised. […]