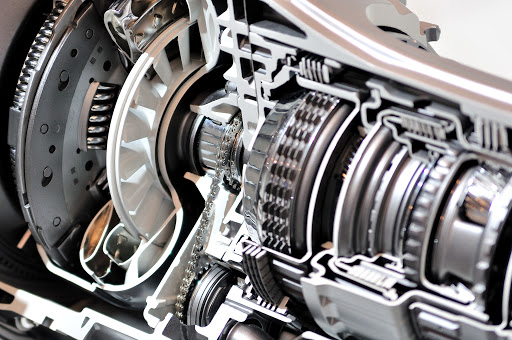

The most basic four-speed manual in a car from the ’60s to the most high-tech six-speed in a car of today, the principles of a manual gearbox are the same. The driver must shift from gear to gear. Normally, a manual gear bolts to a clutch housing (or bell housing) that, in turn, bolts to the back of the engine. If the vehicle has front-wheel drive, the transmission still attaches to the engine in a similar fashion but is usually referred to as a transaxle. This is because the transmission, differential, and drive axles are one complete unit. In a front-wheel-drive car, the transmission also serves as part of the front axle for the front wheels. In the remaining text, transmission and transaxle will both be referred to using the term transmission.

Function of Transmission

The function of any transmission is transferring engine power to the driveshaft and rear wheels (or axle half shafts and front wheels in a front-wheel-drive vehicle). Gears inside the transmission change the vehicle’s drive-wheel speed and torque in relation to engine speed and torque. Lower (numerically higher) gear ratios serve as torque multipliers and help the engine to develop enough power to accelerate from a standstill.

The function of any transmission is transferring engine power to the driveshaft and rear wheels (or axle half shafts and front wheels in a front-wheel-drive vehicle). Gears inside the transmission change the vehicle’s drive-wheel speed and torque in relation to engine speed and torque. Lower (numerically higher) gear ratios serve as torque multipliers and help the engine to develop enough power to accelerate from a standstill.

Power And Torque

Initially, power and torque from the engine comes into the front of the transmission and rotates the main drive gear (or input shaft), which meshes with the cluster or countershaft gear — a series of gears forged into one piece that resembles a cluster of gears. The cluster-gear assembly rotates any time the clutch is engaged to a running engine, whether or not the transmission is in gear or in neutral.

Types Of Manual Transmissions

There are two basic types of manual transmissions. The sliding-gear type and the constant-mesh design. With the basic — and now obsolete — sliding-gear type, nothing is turning inside the transmission case except the main drive gear and cluster gear when the trans is in neutral.  In order to mesh the gears and apply engine power to move the vehicle, the driver presses the clutch pedal and moves the shifter handle, which in turn moves the shift linkage and forks to slide a gear along the main shaft, which is mounted directly above the cluster. Once the gears have meshed, the clutch pedal is released and the engine’s power is sent to the drive wheels. There can be several gears on the main shaft of different diameters and tooth counts, and the transmission shift linkage is designed so the driver has to unmesh one gear before being able to mesh another. With these older transmissions, gear clash is a problem because the gears are all rotating at different speeds.

In order to mesh the gears and apply engine power to move the vehicle, the driver presses the clutch pedal and moves the shifter handle, which in turn moves the shift linkage and forks to slide a gear along the main shaft, which is mounted directly above the cluster. Once the gears have meshed, the clutch pedal is released and the engine’s power is sent to the drive wheels. There can be several gears on the main shaft of different diameters and tooth counts, and the transmission shift linkage is designed so the driver has to unmesh one gear before being able to mesh another. With these older transmissions, gear clash is a problem because the gears are all rotating at different speeds.

[…] Looking directly at the front of the vehicle, camber refers to the tilt in (+) or out (‐) of the bottom half of the […]

[…] from the road’s surface. While people way back then already started using padded cushions to lessen the impact of these forces on their butts, the ride was still far from comfortable. Such systems, […]

[…] addition to the type, you’ll want to consider these factors when buying an auto […]