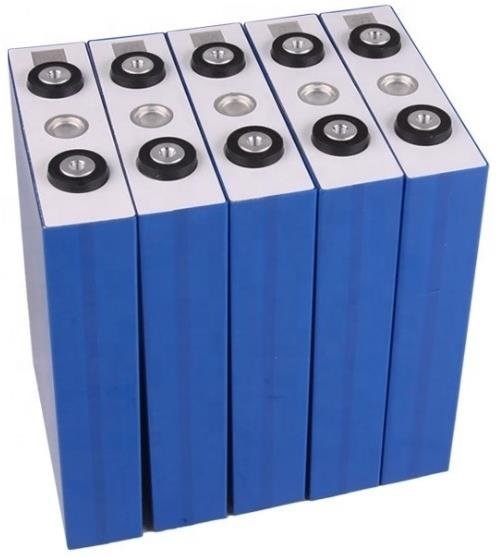

The Lithium Iron Phosphate (LFP) battery is a type of rechargeable lithium battery that has gained significant attention in the automotive and energy storage industries. Known for its high safety standards, long cycle life, and superior thermal stability, the LFP battery is emerging as a preferred choice for electric vehicles (EVs) and renewable energy applications.

Unlike traditional lithium-ion batteries, which often utilize nickel manganese cobalt (NMC) or nickel cobalt aluminum (NCA) chemistries, LFP batteries substitute cobalt with iron phosphate. This chemistry change not only improves safety but also enhances environmental sustainability, making LFP batteries a viable long-term solution for energy storage.

Lithium Iron Phosphate Battery vs. Lithium-ion Battery

Although both LFP and lithium-ion batteries belong to the lithium battery family, they exhibit key differences that influence their performance, efficiency, and safety in real-world applications.

1. Safety & Thermal Stability

1. Safety & Thermal Stability

Safety is one of the biggest advantages of LFP batteries over traditional lithium-ion batteries. Due to their stable phosphate-based chemistry, LFP batteries are less prone to overheating, fire, or thermal runaway. This is a critical feature, especially for applications such as electric vehicles like the Kia EV5 FWD Kia EV5 FWD, where passenger safety is paramount.

In contrast, NMC and NCA lithium-ion batteries contain cobalt and nickel, which are more susceptible to thermal instability, leading to overheating and potential battery fires under extreme conditions.

2. Energy Density

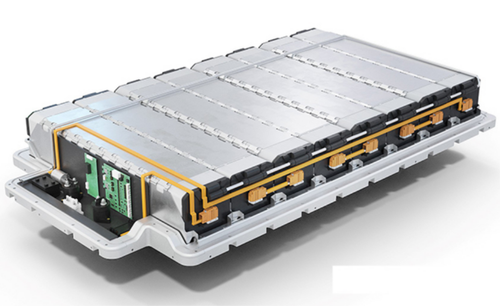

One major factor in the comparison of lithium-iron phosphate batteries vs Lithium-ion batteries is energy density. LFP batteries typically offer an energy density of 90-160 Wh/kg, whereas NMC and NCA batteries can achieve 150-250 Wh/kg. This means that lithium-ion batteries store more energy per unit of weight, making them preferable for applications where space and weight are constraints, such as high-performance electric sports cars.

However, despite lower Lithium Iron Phosphate battery energy density, LFP batteries compensate with better longevity, stability, and cost-effectiveness, making them suitable for hybrid vehicles like the Kia Sportage HEV.

3. Longevity & Cycle Life

LFP batteries exhibit a significantly longer cycle life than traditional lithium-ion batteries. A well-maintained LFP battery can last between 2,000 and 5,000 charge cycles, while NMC and NCA batteries typically sustain 500 to 1,500 cycles before their capacity degrades noticeably.

For drivers seeking long-lasting and efficient battery solutions, LFP batteries are a more reliable option for vehicles such as the Kia Sportage Alpha and the Sportage FWD.

4. Sustainability & Environmental Impact

Another significant advantage of LFP batteries is their sustainability. Unlike NMC and NCA batteries, LFP batteries do not contain cobalt, a rare and environmentally controversial element. Mining cobalt is associated with ethical concerns, including human rights violations and environmental degradation.

By eliminating cobalt, LFP batteries provide an eco-friendly alternative that aligns with global sustainability goals, making them an excellent choice for consumers looking to reduce their carbon footprint.

Lithium Iron Phosphate Battery Energy Density and Performance

A common question surrounding LFP batteries is how their energy density impacts real-world performance. While they do have a lower energy density compared to NMC/NCA batteries, they compensate with other attributes such as:

Higher Efficiency: LFP batteries maintain a stable voltage throughout discharge, ensuring consistent power output.

Higher Efficiency: LFP batteries maintain a stable voltage throughout discharge, ensuring consistent power output.- Improved Heat Resistance: They remain cooler during operation, reducing the need for complex cooling systems in EVs.

- Faster Charging: LFP batteries can support rapid charging technologies, reducing downtime for electric vehicle users.

These characteristics make LFP batteries an attractive option for EVs, hybrid vehicles, and renewable energy storage solutions.

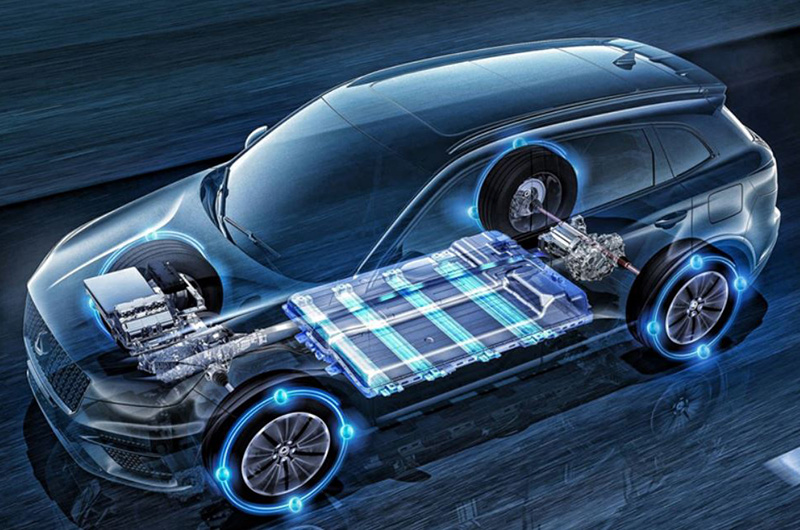

Applications of LFP Batteries in the Automotive Industry

LFP batteries are widely used across various sectors, particularly in the automotive industry. Some key applications include:

Electric Vehicles (EVs): Many automakers, including Kia, are integrating LFP batteries into their EV lineup due to their superior longevity and affordability.

Electric Vehicles (EVs): Many automakers, including Kia, are integrating LFP batteries into their EV lineup due to their superior longevity and affordability.- Hybrid Vehicles: LFP batteries improve the efficiency and reliability of hybrid powertrains, making them ideal for vehicles like the Kia Sportage HEV.

- Renewable Energy Storage: LFP batteries are extensively used for solar and wind energy storage, ensuring sustainable and uninterrupted power supply.

Advantages of Lithium Iron Phosphate (LFP) Batteries

- Exceptional Safety: Minimal risk of overheating or fire.

- Longer Lifespan: 2,000-5,000 charge cycles, ensuring longevity.

- Fast Charging Capability: Reduces wait times for EV users.

- Environmentally Friendly: Free of cobalt and toxic heavy metals.

- Stable Performance: Delivers consistent voltage and efficiency.

LFP Battery Maintenance & Protection

To extend the lifespan and maintain the efficiency of LFP-powered vehicles, regular maintenance and protective coatings are essential. Some useful protective services include:

- 3M Glass Coating Protection to shield vehicles from UV damage and environmental pollutants.

- Undercoating Car Protection to prevent rust and corrosion, ensuring long-term durability.

Additionally, owners can schedule routine maintenance through the Online Service Appointment Form for professional checkups.

Conclusion: The Future of LFP Batteries

The future of Lithium Iron Phosphate (LFP) batteries looks promising, driven by advancements in technology and increased demand for sustainable energy storage solutions. With their high safety, extended lifespan, and cost-effectiveness, LFP batteries are set to become a dominant force in the electric vehicle industry.

Consumers exploring Kia’s latest hybrid and electric models can check out the Price List for up-to-date pricing or submit inquiries via the Online Inquiry Form.